Troll Kart

Hands on Brakes and Throttle Pedal, Get Set, Go!

summary_

Troll Kart was born when inexperience, miscalculation, and perseverance come together into a high performing beast that was unfortunately not very robust. However, my team and I were very proud of was we achieved because none of us had ever used Computer-Aided Design (CAD) software before until the whole project started! Nonetheless, aside from the less-than-convincing front left axle, Troll Kart topped the speed trap record amongst the other electric go-kart built by the 2014 Global Leadership Program (GLP) batch of students.

Year 2014

Team Stevanus Satria, Zhou Minglong, Yap Qi Xuan

My Role Mechanical Engineer and Designer

Software SolidWorks, CorelDRAW

Hardware Pretty much anything found in a Fabrication Lab, including Water Jet, Laser Cutter, CNC Lathe, and CNC Mill

background_

The Global Leadership Program (GLP) was the flagship exchange program offered by the Singapore University of Technology and Design (SUTD). It involved spending 10 weeks in the world-renowned Massachusetts Insitute of Technology (MIT) campus learning various subjects related to engineering and architecture. Every year, hundreds of students compete for one of the 30+ slots to participate in the highly-coveted program.

Therefore, I was really fortunate to be one of the few selected to participate in the 2014 Edition of the Global Leadership Program. The whole preparation got me really excited right up to the departure date, and the moment we settled in and set foot on the iconic Killian Court, everything felt so surreal.

One of the core subjects that we had to learn throughout the program was how to build an electric go-kart from scratch. For the first few weeks, we would be taught new concepts on mechanical and electrical engineering in the context of go-kart design, and for the rest of the time, we would be given complete liberty to ideate, design, and fabricate our very own electric go-kart. At the end of it all, we would all be racing each other around a track built by our instructors within the MIT campus.

It was this challenge/subject that gave birth to Troll Kart, the process of which will be outlined in the coming sections of this documentation.

To ideate, design, and fabricate a fully-functional electric go-kart from scratch within 10 weeks

THE GOAL

research_

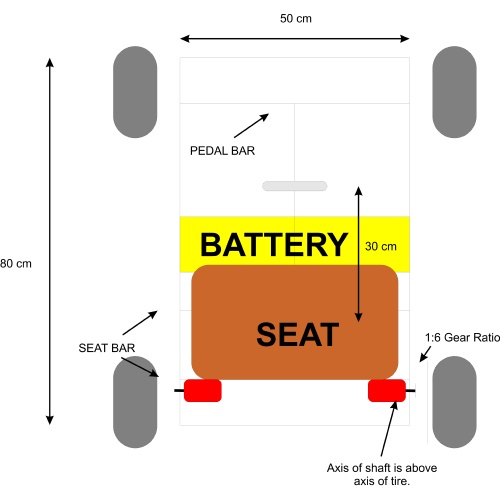

From the get-go, our team decided that the parameter we would be focusing on was speed. Hence, for our chassis design, we decided to go with a simple four-wheeled with two rear-mounted motors powering each of the rear wheels. The measurements were based on precedent go-karts made by our instructors, which we believed would allow us to fit all the components within the chassis (spoiler alert: one particular component was misjudged).

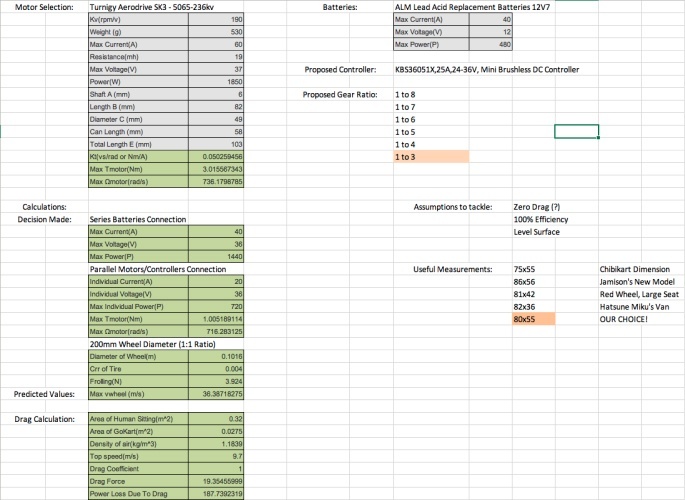

However, when trying to figure out the details, we were quickly overwhelmed by the number of variables available for us to tweak (the power of our brushless DC (BLDC) motor, gear ratio, motor controller, and many more). As such, for the first week or so we were completely unsure where to start. However, upon consulting one of the more experienced teams, we understood that the way to go was to do iterative tuning, whereby we could start by fixing one of the free variables, whip up calculations for the other variables’ values, and then look at the result and before making changes.

We thus started by doing up a simple calculation to understand the amount of torque needed to get the go-kart and its driver to move from stationary. With this, and pre-selecting the BLDC motor for a start, we were able to construct a spreadsheet to come up with possible values for the rest of the variables. From then on, it was a matter of fitting our bill of material into the budget constraint and with that, the parts for our go-kart were frozen!

CAD design, fabrication, and assembly_

Designing the whole go-kart on SolidWorks took a tremendous amount of time, given the scale of the project we had on hand and the number of people we had on the team. We started off by CAD-ing the chassis of the go-kart, followed by the individual purchased parts, and then our custom mountings, before finally assembling all of them into a CAD assembly. We actually had to CAD some of the purchased parts ourselves as they were not available online.

The tight deadline also meant that we could not wait until the whole go-kart was modeled and assembled before going into the fabrication phase. As such, whenever a component or sub-assembly looked and felt correct, we had to go ahead and book slots in the Fabrication Lab to get them prototyped. For some materials, we were given unlimited supplies. However, for others, we only had the ones handed or purchased by us, so any mistakes would bear dire consequences!

Fortunately, we were quite thorough and meticulous in our dimensioning and tolerance provisioning that most of our parts could be assembled without any hiccups. Unfortunately, there were two problematic areas:

- Our front brake discs design did not account for the thickness of the screw heads. As such, the wheel was unable to spin freely as the screw head was unable to pass through the brake calipers! To make matters worse, the brake discs were made using aluminum sheets which were limited. Thankfully, by creating a countersunk we were able to make the screw heads flushed against the brake discs.

- We made a mistake in our chassis dimension such that there wasn’t enough legroom to safely mount our foot pedal on the chassis. However, by the time we discovered this, we had used up all our budget and were thus unable to purchase a hand throttle as a replacement. However, we refused to let this be a blocker in getting our kart out into the race track. Hence, we decided to use the foot pedal as a hand throttle instead, and ended up mounting it on the steering wheel!

The second point above, coupled with a few other shenanigans that we did (adding a wheel onto our bucket seat for “extra cushion” and doing up a “seatbelt” using rubber bands), was what gave rise to the monicker “Troll Kart”. Hence, may we present to you, the fully assembled Troll Kart, which was the first kart to be completed amongst the other go-karts of the 2016 Global Leadership Program batch!

evaluation_

Given that this was our first ever electric go-kart building project, I was really satisfied with how we were able to not only get a working go-kart out but also be the fastest go-kart on the track while attaining relatively good reliability. Aside from the shoddy front brake discs, of which the left one failed midway through my lap, it was a really fun go-kart to ride around as well!

After the whole Global Leadership Program ended, SUTD arranged for all the go-karts to be shipped back to Singapore. By then, some of us, including myself had founded the SUTD EV Club dedicated to teaching fellow undergraduates who did not get the chance to attend GLP how to build an electric go-kart. Our first task was to reassemble all the go-karts, and then upon testing each one of them, took apart the ones that couldn’t run well in order to enhance the others that do run. As we managed to get Troll Kart up and running, we ended up reusing and buying some parts to improve its weaknesses.

At the end of the day, Troll Kart went on to be one of the units used for test runs during any major campus events such as Open Houses for the next two years 🙂